Aluminium Tensile Test Failure - CT Analysis: Introduction

Tensile testing is an essential method to evaluate the strength and reliability of aluminium weldments. In this case, a weldment failed unexpectedly during a tensile test. To understand the root cause, our team performed an advanced X-ray Computed Tomography (XCT) scan, a 3D scan technique which reveals extensive porosity within the weldment. This internal defect significantly reduced its strength and led to premature failure.

Tensile Test Failure of Aluminium Weldment

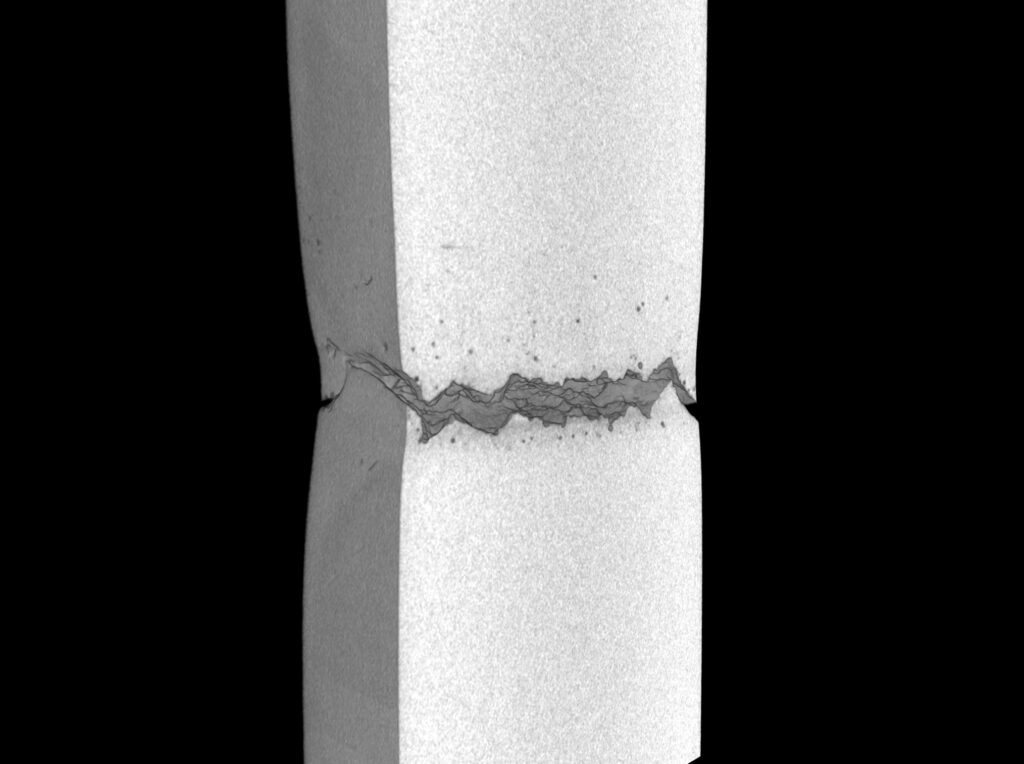

During the aluminium weldment tensile test, the specimen fractured at a lower-than-expected load. Such premature failure is often linked to welding defects, porosity, or poor fusion. To verify the cause, the failed weldment was subjected to non-destructive XCT scanning, a technique capable of revealing hidden flaws.

Role of X-ray CT Scan in Weldment Failure Analysis

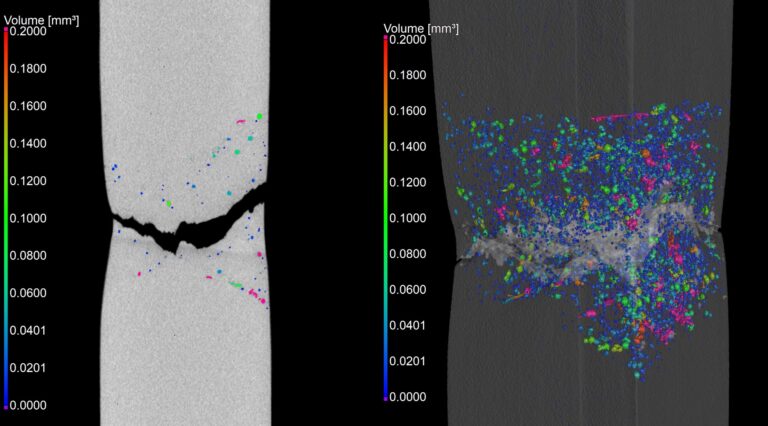

XCT scanning allows for high-resolution, three-dimensional visualization of a weldment’s internal structure. Unlike destructive inspection methods, it provides a complete view of hidden porosity, cracks, and inclusions without damaging the sample.

In this case, the XCT scan revealed:

Widespread porosity in the aluminium weldment

Pores concentrated near the weld joint, acting as stress concentrators

Early crack initiation points that propagated under tensile loading

Porosity as the Root Cause of Failure

The scan confirmed that internal porosity weakened the weldment by reducing the effective load-bearing cross-section. Under tensile stress, cracks formed more easily around the pores, causing the weldment to fail prematurely. This demonstrates how weld quality directly impacts mechanical performance.

How Our Services Can Help

At Professional Testing Services, we provide professional tensile testing services for weldments of various material grades as well as advanced 3D Scan XCT scanning services to identify internal defects and provide qualitative and quantitative information of a sample. By combining mechanical testing with non-destructive evaluation, we help manufacturers and fabricators ensure weld reliability, structural integrity, and compliance with industry standards.

Talk to us today

If you need reliable tensile testing or X-ray CT scanning services for aluminium weldments and other materials, our team is here to help. We deliver accurate, detailed failure analysis to support your quality assurance and R&D needs.

Contact us today to learn how our testing services can improve the performance and safety of your products.

Professional Testing Services (PTS) is currently offering FREE trial scans on our X-ray Computed Tomography services to allow engineers worldwide to understand the capabilities of advanced radiography techniques.

All new customers are entitled to a session of free consultation and CT scan service.

*The desired scan with the optimized parameter will be charged at the total price with an additional discount at PTS’s discretion.