PROBE FERRITE DEFICIT WITH MAGNETIC INDUCTION

The importance of ferrite content & why there’s a need for measurement

Duplex stainless steels are a family of corrosion-resistant alloys. It typically contains 50 % austenite and 50 % ferrite – a phase balance essential in duplex stainless steel. This way helps impart optimum mechanical properties and corrosion resistance. While the austenite phase provides corrosion resistance and impact strength toughness, too much ferrite will reduce toughness. Too little ferrite will reduce the resistance to chloride stress corrosion cracking.

One prime example would be welding. It involves a thermal cycle that may alter the phase balance. It is essential to ensure that phase balance is still within acceptable ranges in the heat-affected zone and weld metal.

Quality control of welded duplex stainless steels usually requires confirmation of an acceptable phase balance by ferrite measurement. Ferrite content measurement can be done on-site via a portable ferrite scope machine. Only an onsite measurement can assure that the processing did not unfavourably change the optimum ferrite content at the expense of mechanical or corrosion-resistance properties.

WHY do we need to measure the ferrite content in duplex stainless steel?

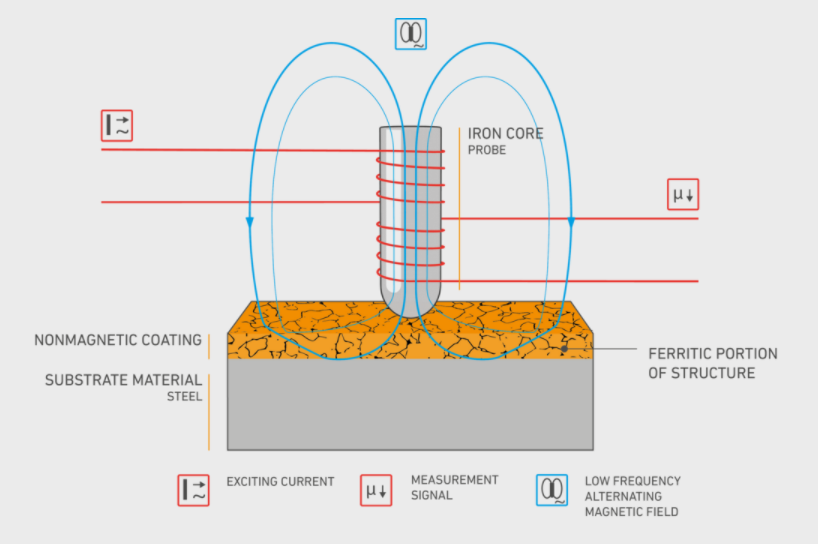

Ferrite testing verifies whether heat treatment applied to the material has reached the required performance balance. Ferrite testing commonly employs magnetic induction to measure the ferrite content of a material, although other methods are used. The delta ferrite content is estimated to better understand an austenitic or duplex stainless steel’s susceptibility to corrosion, susceptibility to solidification cracking and other types of material failure.

Our portable ferrite content

measurement technique

PTSPL’s ferrite content measurement via Fischer ferrite scope – a brand widely recognised in the oil and gas industry. An instrument that uses magnetic induction to measure the ferrite content of a material.

In welding, ferrite testing provides a simple yet instant measurement of the ferrite content, especially in the weldment, which can easily assume unfavourable values either due to unsuitable welding filler materials or through poor heat input or heat removal.

Conversely, in duplex stainless steels, the ferrite content will only influence

- How corrosion-resistant it is

- Its mechanical properties

Having the right ferrite content in the type of stainless steel that is being worked with will provide the correct balance between:

- How tough it is

- How corrosion-resistant it is

- Its ductility

- Whether or not it will crack

Common test methods

BS EN ISO 8249

AWS A4.2M

talk to us today

Our ferrite content testing team ensures that obtained ferrite readings are accurate and can measure Ferrite’s low, medium or high content through complete sets of magnetic induction probes. Contact us today for more information about how we perform ferrite content measurement or request a quote.