Determine steel strength through deformation

With regard to metals, hardness testing determines a material’s strength by measuring its resistance to penetration. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation.

Hardness affects a wide range of physical characteristics, such as how much the metal will wear, scratch, or withstand stress. Foundries, fabricators, manufacturers, metal stockholders, importers and welding inspectors need the reassurance that a metal or alloy will be suitable for a product’s intended use or meets industry specifications.

At Professional Testing Services, we provide impact, tensile and hardness testing at our laboratories using advanced testing equipment. In addition, we have in-house machine shops to specialise in Rockwell, Brinell, and Vickers hardness tests. Our Mechanical department also provides microindentation hardness testing, including Knoop Hardness and Vickers hardness.

How do hardness test work?

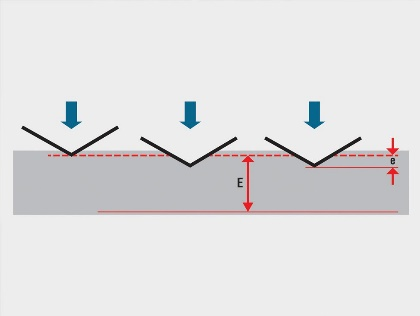

Our team of Hardness test experts will press a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. WThe hardness is determined by measuring the depth of indenter penetration or by measuring the size of the impression left by an indenter.

1) Hardness tests that measure the depth of indenter penetration include: Rockwell, Instrumented Indentation Testing, and Ball Indentation Hardness

2) Hardness tests that measure the size of the impression left by the indenter include: Vickers, Knoop, and Brinell

Our Hardness Tests

1) Rockwell Hardness Test

The Rockwell Hardness Test measures the depth of penetration of an indenter under a specific load, compared to the penetration made by a preload. The permanent deformation caused by the larger load offers information on the material’s hardness.

The penetrator may be either a tungsten carbide ball or a diamond cone. The hardness number is related to the depth of the indentation and the higher the number, the harder the material.

- Generally used for larger sample geometries

- Quick (short test cycle) and cost-effective process

- No specimen preparation required (separation, grinding, embedding)

2) The Vickers hardness test

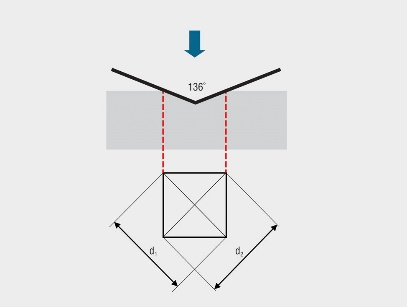

The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the opposite faces at the vertex, which is pressed into the surface of the test piece using a prescribed force, F.

It can be referred to as a micro hardness test method, is mostly used for small parts, thin sections, or case depth work.

Since the test indentation is very small in a Vickers test, it is useful for a variety of applications: testing very thin materials like foils or measuring the surface of a part, small parts or small areas, measuring individual microstructures, or measuring the depth of case hardening by sectioning a part and making a series of indentations to describe a profile of the change in hardness.

- Used for hardness testing of all solid materials, including metallic materials

- Suitable for a wide range of applications as it requires only one type of indenter.

- Includes a sub-group of hardness testing of welds

3) The Knoop hardness test

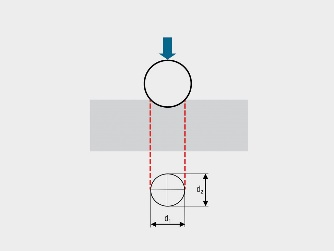

The Knoop micro hardness test is an industry-standard technique for exploring the mechanical hardness of brittle materials or thin samples. It is one of several different test methods used to determine hardness via micro- and nano indentation.

Hardness test result is calculated by measuring the indentation produced by a diamond tip that is pressed onto the surface of a sample. It is suitable for thin and narrow specimens and for testing brittle materials (To prevent crack formation at the indent).

By using lower indentation pressures than the Vickers hardness test, which had been designed for measuring metals, the Knoop hardness test allowed the hardness testing of brittle materials such as glass and ceramics.

- Only a very small sample of material is required

- Used for hard and brittle materials, such as ceramics

Suitable for small elongated areas, such as coatings

Talk to us today

Professional Testing Services can advise you on the most suitable method for your hardness testing project needs. Our experience testing team will provide you with the necessary information to help you ensure the safe and reliable operation of your products. For more information about how we perform testing, or to request a quote, contact us today.